Product

GRP SECTIONAL WATER TANK

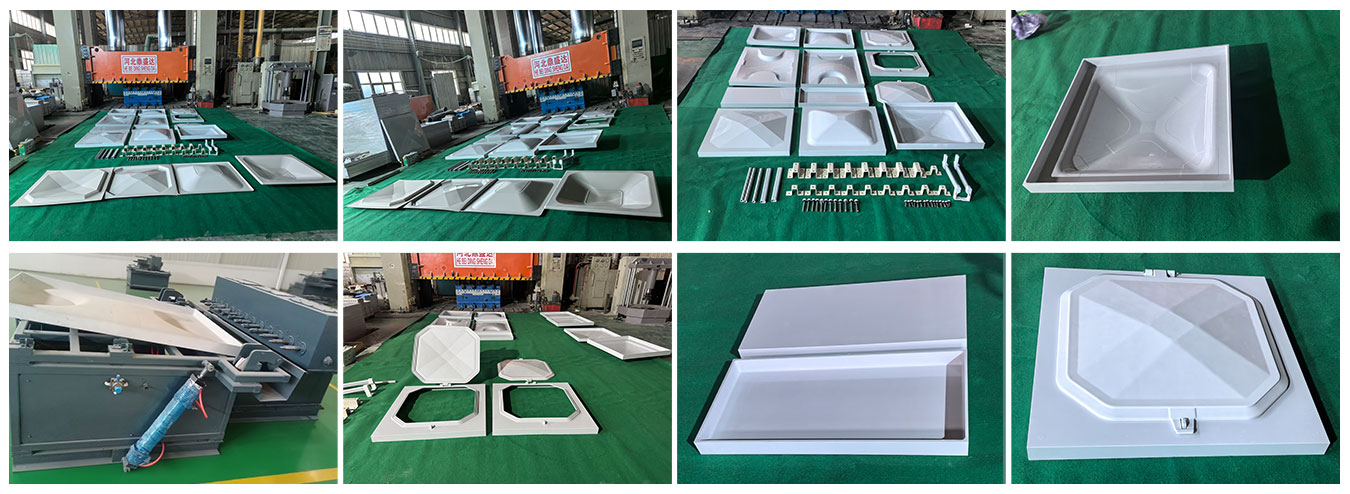

GRP Sectional Water Tank is a new-type water storage solution, the GRP tank is fabricated from high-grade SMC panels. SMC, short for Sheet Molding Compound, is a fiberglass-reinforced plastic formulated with unsaturated polyester resin, reinforcing agents, fillers and glass fibers.

GRP water tank panel are Non-toxic, durable, lightweight and corrosion-resistant, the tank also has an attractive look, requires minimal maintenance, and delivers a long service life.

Available in a wide range of sizes from 1 to 100 cubic meters, the tank can also be customized to meet specific requirements.

Its modular design enables quick and easy installation, making it ideal for various applications including hospitals, shopping malls, supermarkets, schools and residential complexes.

The FRP assembled water tanks we offer come in white, with thickness tailored to tank size. Boasting high compressive strength, they are equipped with float valve overflow protection and liquid level indicators to ensure safe, reliable operation and easy management.

For more information on tank specifications, customization services or installation guidance, please feel free to contact us. We are ready to provide you with professional solutions.

Highlight

UV PROTECTION

UV PROTECTION

WRAS CERTIFIED

WRAS CERTIFIED

MAINTENANCE FREE

MAINTENANCE FREE

HOT PRESSED SMC PANELS

HOT PRESSED SMC PANELS

40MM INSULATION THICKNESS

40MM INSULATION THICKNESS

HDG EXTERNAL REINFORCEMENT

HDG EXTERNAL REINFORCEMENT

SS316 INTERNAL REINFORCEMENT

SS316 INTERNAL REINFORCEMENT

Product feature description

Grp Water Tank Features

Easy installation regardless of space and size. Simple disassembly and reassembly of water tank.

Absolute Water Tightness

Feature absolute water tightness by applying high-stability sealing type.

Hygiene

Complete block out of external light for preventing growth of bacteria.

Durability

Applied stainless steel for the internal structure to prevent corrosion or rust and hot dip galvanized the external structure for corrosion resistance.

Outstanding Insulation & Dew-Proofing

It has excellent heat retention using urethane foam insulation, and effectively prevents condensation, ensuring excellent usability.

Special order production

Antibacterial water tank can be specially manufactured upon production order.

Simple Assembly

Use of standardized parts that require assembly at construction sites, which facilitate mobility to small spaces, expanding tanks, and reinstalling tanks in a different location.

Easy to Clean

The drainage hole located on the bottom of the tank facilitates the cleaning. The square-type manhole maximizes the space enabing easy access by people.

DING TANKS MAIN FACILITIES AND CAPACITY

| MIXTURE MACHINE | 1 UNIT |

PRESSING MACHINE FOR GRP WATER TANK PANEL | 3000 TON, 1 UNIT |

| 1800 TON, 1 UNIT | |

| 1250 TON, 2 UNIT | |

| 630 TON, 1 UNIT | |

| 315 TON, 8 UNIT | |

| DRILLING MACHINE | 3 UNIT |

| INSULATING INJECTION MACHINE | 1 UNIT |

| PRESSURE TESTER | 3 UNITS |

| PANEL CAPACITY / MONTH | 12000 PCS |

GRP PANEL LAB TEST PROPERTIES

No. | Test Items | Results |

| 1 | Tensile Strength | 117 Mpa |

| 2 | Tensile Modulus | 15.1 Mpa |

| 3 | Flexural Strength | 203 Mpa |

| 4 | Flexural Modulus | 13.8 GPa |

| 5 | Compressive Strength | 231 Mpa |

| 6 | In-plane Shear Strength | 90 Mpa |

| 7 | Impact Toughness | 94.1 KJ/m³ |

| 8 | Barco Hardness | 56 |

| 9 | Thermal Conductivity (100 ℃) | 0.438 W/m·k |

| 10 | Mean coefficient of linearthermal expansion | 25x10-6 (1/℃) |

| 11 | Water absorption percentage (24 hour immersion) | 0.0961 (%) |

| 12 | Fiber mass content | 36.0 (%) |

| 13 | Density (23℃) | 1.80 x 103 (kg/m3) |

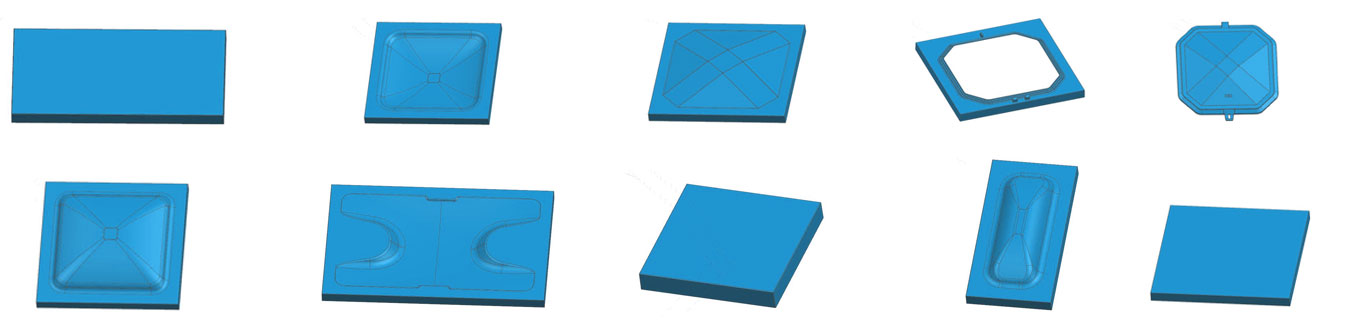

PANEL TYPE & SHAPES

PANEL TYPE & SHAPES

| Roof Panel | 1000*1000 |

| Manhole | 1000*1000 |

Wall Panel | 1000*1000 |

| 1000*1500 | |

| Bottom Panel | 1000*1000 |

| 1000*500 | |

| Flat Panel | 1000*1000 |

| 1000*500 | |

| 500*500 |

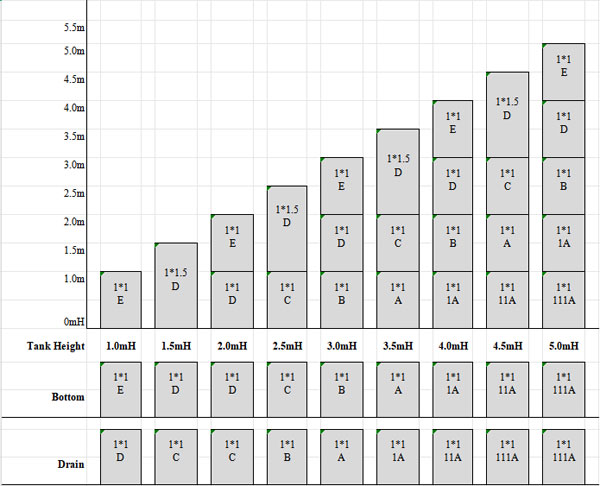

CONFIGURATION

CONFIGURATION

Easy capacity design

Various sizes of water tank panels can meet the client’s requirements of different capacities.

| Available Design Height and Capacity | |

| Available Height | Available Capacity |

| 1.0 ~ 5.0Mh / 0.5m distance | 1 ~ 3000 ton |

Water Tightness Sealant

High weatherproof and elasticity of sealing material brings better water tightness. Designed specifically for doors, windows, and automotive applications, our advanced sealing strips leverage these properties to create a reliable barrier against rain, snow, and moisture intrusion. The material's robust weather resistance ensures long-lasting performance even in harsh conditions, while its superior elasticity allows it to maintain a tight seal despite temperature fluctuations or structural movements. This combination not only enhances water tightness but also improves energy efficiency by preventing drafts, contributing to a more comfortable and durable environment.

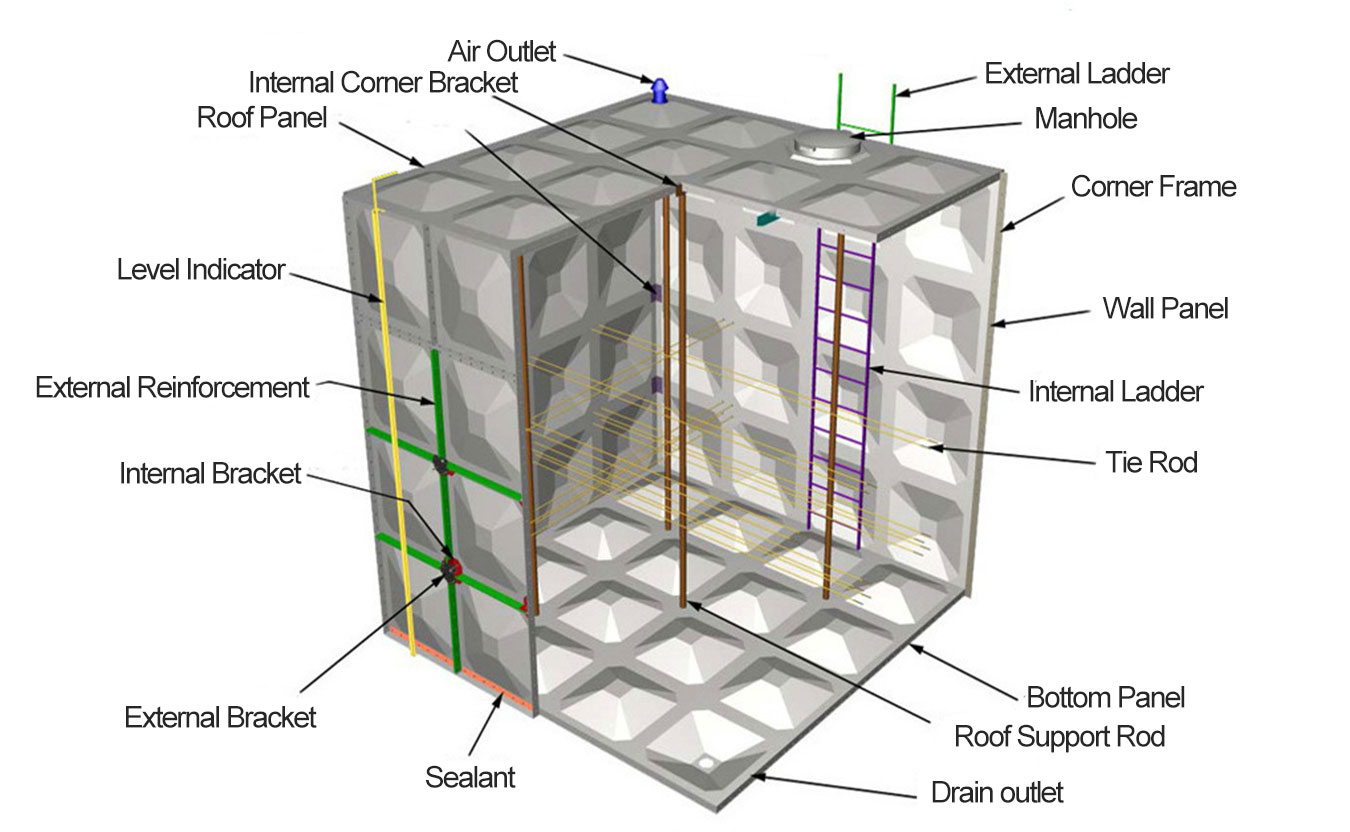

GRP sectional water tank includes:

1. Panels ( Bottom panel, wall panel, roof panel and manhole);

2. Internal parts ( Internal ladder, tie rod, support rod, bracket, flanges and rubber); STS316 / STS304 / FRP

3. External parts ( External ladder, reinforcement, braket, bolts and nuts); STS304 / HDG

4. U-steel base (surface treatment can be painted or hot dipped galvanized or stainless steel).